Roofing Projects: Early-Phase Focus, Long-Term Success

Attention to design, warranties and qualified contractors up front can be the difference between success and failure

The process of replacing or recovering an existing roof on a commercial or institutional facility involves decisions in a number of crucial areas. The standards established during a project’s pre-construction phase can aid and mitigate risk management during construction and sustainable models for future building maintenance.

For these reasons, it is important that maintenance and engineering managers carefully research roofing systems and have general guidelines in place for such projects related to roof design, roofing warranties, prequalifying subcontractors, and comprehensive roof maintenance.

Roof system design

Accurately designing roofing systems for institutional and commercial facilities is critical to contributing to the total building energy efficiency and to projecting construction and maintenance costs. For managers, one important challenge is understanding typical roofing terminology related to applicable roofing assemblies.

Roofing membrane. Most new-construction commercial projects are designed with built-up roofs to meet energy requirements. Some built-up roof products, such as asphalt roofing, have become less common due to advances in newer roofing technologies, including single-ply roofing membranes.

Two types of asphalt roofing are modified bitumen — SBS and AAP — and a traditional built-up roof (BUR), which can be installed with cold-process adhesives, hot torches, and asphalt.

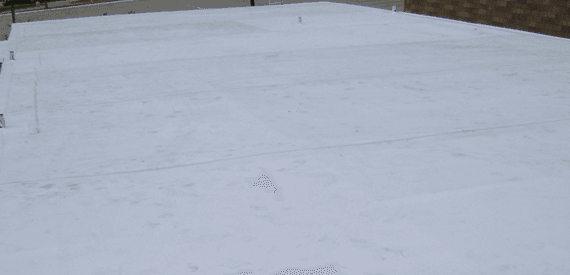

The two types of single-ply roofs include: thermoset systems, known as EPDM and composed of rubber; and thermoplastic systems, known as TPO and PVS, which are composed of plastic. TPO is a newer alternative to EPDM and is gaining popularity due to its inherent characteristics of strength and durability, as well as its lower installation cost.

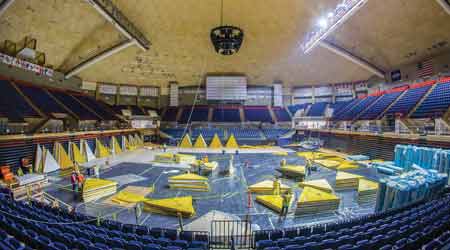

Insulation and coverboards. These components protect the roofing membrane and ensure the building’s energy efficiency. Three types of foam-insulation products account for most of the insulation used in commercial building roofing systems: polyiso, or polyisocyanurate; extruded polystyrene (XPS); and expanded polystyrene (EPS).

Insulation typically is specified during the design phase for thermal requirements, but its properties lend themselves to meeting fire requirements, moisture resistance, and impact resistance. Typically, the design team provides an energy analysis for the total building enclosure, including R-value requirements at the roofing assembly. Many managers choose to exceed the minimum requirements because it will lead to better overall energy performance and lower utility bills.

Two types of coverboard include glass mat gypsum board and high-density polyiso. Like insulation, both coverboard types provide thermal resistance, fire resistance, dimensional stability, moisture resistance, and strength. In general, the coverboard prepares the substrate or insulation to receive the roofing membrane. The coverboard protects the insulation when hot asphalt, solvents and adhesives are used during installation. If an asphalt roofing membrane is not applied in the design, the coverboard is not required to be part of the overall roofing assembly.

Attachment systems. Manufacturers typically specify and warranty their own proprietary insulation and coverboard attachment systems. The most common attachment types are fully adhered, mechanically attached, and ballasted systems.

Fully-adhered attachments have the highest wind-uplift test-passing rate, and they conform to a variety of substrates and roof configurations. Fully adhered attachment roofs typically offer warranties up to 30 years.

Mechanically-attached systems also have high wind-uplift approvals and generally are less labor-intensive to install than fully adhered attachments. Mechanically attached systems typically offer warranties up to 20 years.

Ballasted attachments, known as loose-laid systems, offer the lowest installation cost and provide the greatest fire resistance. Typical ballasted roofs offer warranties up to 20 years. Managers must consider a few factors during design for a ballasted roofing system. Maintenance for ballasted roofs is more intensive because it is difficult to locate potential leaks..

Comments

Source: Commercial Roofing

No comments yet.