Roof Coatings: Specification Based on Facility Needs

Understanding facility needs, long-term goals and the latest coating options is essential for effective applications

Before a roof coating can be effectively applied to a commercial or institutional facility, it is vital that maintenance and engineering managers understand which kind of coating would work best on the roof in question.

Roof coatings offer managers no shortage of options, so it is essential to understand advances in roof coating technology, effective application methods based on the specific roof substrate, and the overall goals of coating specification and application.

“There have been great developments in roof coatings technologies over the past several years, including enhancements in dirt pickup resistance (DPUR), ponding water resistance, and direct bond adhesion to common roofing substrates without the need for primers,” says Edward Leshansky with Tropical Roofing. “These three attributes are critical to the longevity and performance of the coating over time.”

Sorting through options

One of the most impactful advances in roof coatings over the past several years has to do with the coatings’ chemistry and makeup.

“Chemistry advances are typically aimed at faster cure, improved application windows, and better resistance to environmental exposures,” says Kirk Goodrum with Siplast. “Conventional coatings were aluminum, bituminous, or basic water-based acrylic. Today, the selection includes silicones, urethanes, acrylic hybrids, advanced emulsions, silane terminated polymers, poly methyl methacrylates, polyureas and many more.”

In particular, the advances improve the protection that coatings offer against such challenges as ponding water, mold, and mildew.

“Improved ponded-water resistance in coatings allows for more roofs to become candidates for coatings applications, as certain coatings are now rated to withstand ponded water conditions, as opposed to tearing up the roofing substrate and correcting the slope of the roof,” Leshansky says. “Direct-bond coatings allow for higher performing, less labor-hour applications of coatings, due to not having to pre-treat the roof with a primer.”

While the latest advances in roof coating technology can maximize the product’s effectiveness and lifespan after application, managers still need to understand no single coating offers a solution for all jobs. Each application needs to be evaluated on its own.

“The options in today’s market are overwhelming,” Goodrum says. “The first thing that a manager should ask is, ‘What is the purpose for applying the coating?’ If it is for life extension or changing the surface characteristics, then the coating is not likely intended to be primary waterproofing. This is generally for a roof membrane that is not experiencing failures but may be near the end of its service life. In many cases, the coating is only expected to last for five-to ten years.

“If failures are being experienced by the roof system, then a roofing professional should evaluate the roof for water intrusion and can assist in selecting the most appropriate course of action.”

The type of facility in question also can go a long way in helping managers determine the most appropriate roof coatings for the application.

“In buildings like hospitals, schools, and elderly housing, there might be a preference to utilize low VOC (volatile organic compounds), low-odor products,”says Chris Salazar with Karnak Corp. “Overall budget restrictions may also limit the building owner’s choice.

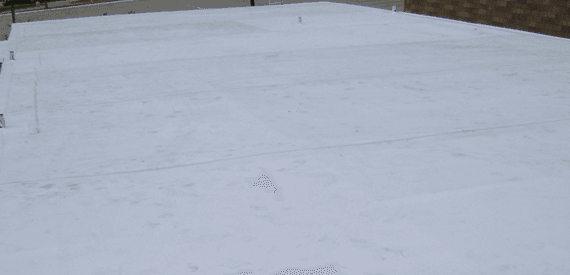

“In regards to reflectivity and emissivity, managers should remember that once a coating has obtained Energy Star rating, the reflective coatings all provide relatively similar energy savings,” Salazar says. “The only difference is that Energy Star rated aluminum coatings, while not as reflective as the white coating countertypes, offer lower emissivity, which may prove beneficial in cooler climates. The good news is that there is a broad range of reflective coating options that can extend the life of the roof, help avoid roof replacement, and save energy.”

Reflectivity and emissivity directly correlate to the amount of heat, light and energy reflected and refracted off the coating. In general, managers of facilities in warmer climates should consider specifying a reflective roof coating, while managers in facilities in cooler climates should consider specifying a more emissive coating.

“Higher numbers, greater than 0.85, ensure that your coating will minimize the amount of heat and energy that is beating down on your roof, ultimately resulting in a cooler inside temperature,” Leshansky says. “A highly reflective and highly emissive coating, coupled with adequate and code compliant amounts of insulation, will ensure that your building stays cool in the summer and warm in the winter.”

Comments

Source: Commercial Roofing

No comments yet.