8 Technology Developments Reshaping High-Performance Building Exteriors

From blue roofs to green walls, these high-performance exteriors elements can make buildings more energy efficient and sustainable.

From blue roofs to green walls, these high-performance exteriors elements can make buildings more energy efficient and sustainable.The green roof on the LEED Platinum Vancouver Convention Centre features more than 400,000 indigenous plants and grasses.

By Peter M. Babaian, Matthew J. Normandeau, and Emily R. Hopps Roofing Article Use Policy

The building enclosure is crucial to an energy-efficient, high-performing building. Today, facility managers are pushing toward greater energy efficiency and are challenged with the reality of aging infrastructure. Technology updates and changes in roofing, fenestration, and cladding products and strategies respond to the energy-efficient and high-performance demands of the marketplace.

Over the years, the industry has moved from heavy, bulky masonry buildings with limited fenestration and minimal roof insulation, to light-weight and open buildings with lots of glass and highly insulated roofs. Today, building enclosures comprise many different products, each intended to serve a particular and sometimes singular function, with specific and sometimes proprietary installation requirements. As a result, the building enclosure is now more complicated than ever to design and construct. For facility managers, understanding the technology developments in building enclosures and specific benefits and considerations of these advancing technologies is an important step to making sure to pick the right products for a particular building.

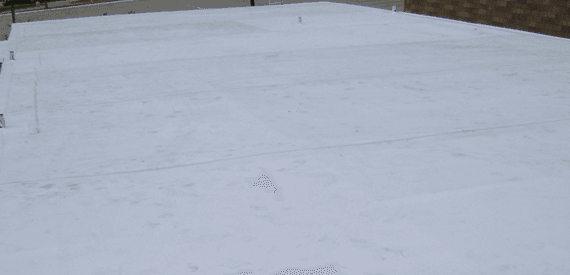

1. Cool roofs

For years, most roof surfaces were covered with a black or dark-colored roofing membrane, given the durability of tar and asphalt in traditional roofing materials. But dark-colored roof surfaces increase in temperature when exposed to the sun. The higher surface temperatures increase heat gain through the roof system, consequently raising the cooling loads and reducing the roofing system’s overall energy efficiency. To address this inefficiency, the industry evolved to include light-colored roofing membranes that reflect the sun’s rays and absorb less heat to remain “cooler” than their predecessors.

Use of cool roofing systems is now a requirement of many jurisdictions and other benchmarks that dictate roofing selection, and energy modeling demonstrates tangible energy savings are available, especially in cooling climates. Reducing the in-service temperature of the roofing membrane also reduces thermal cycling of the roofing system, improving durability. The reflective benefits of cool roofs can diminish over time as the roof gets dirty — so regular cleaning may be required to keep the energy benefits intact.

2. Green roofs

Planting vegetation over occupied space has been common in the industry for many years. However, it was historically primarily at the plaza deck level, essentially on grade, often without critical underlying occupied space. In 2004, Chicago became the first city to mandate sustainable features on buildings receiving city financial assistance. This quickly resulted in a green roof phenomenon that has seen more than 5 million square feet of green roofs installed throughout the city. The trend is not limited to Chicago; green roofs are now common throughout the United States and the world. They are a good way to control stormwater runoff, reduce cooling and heating loads, and provide opportunities for occupant enjoyment and leisure.

The vexing problem for green roofs has always been tracing water leakage through the system given the overburden removal required to access the waterproofing membrane. To help reduce this potential issue, the industry has responded with innovations ranging from embedding permanent grids into the waterproofing membrane for electric conductance testing, to fully-adhering or compartmentalizing the waterproofing membrane to the roof deck to isolate leakage to confined areas. Further improvements in the overburden systems have allowed these roofs to be installed on new and existing buildings in thin, tray systems that reduce the added weight on the structure and simplify future removal of overburden. As a result, green roofs are more reliable and less costly, and therefore, more likely to be incorporated into projects.

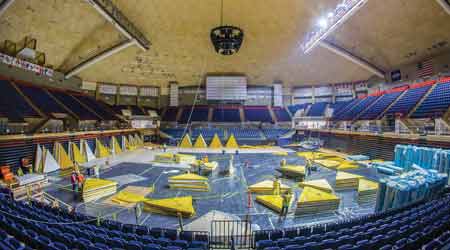

3. Blue roofs

Blue roofs are a new type of roofing system that attenuate peak stormwater flow from the roof to accommodate the limited capacity of an existing antiquated infrastructure, manage storm runoff in highly developed areas, or control more frequent high-intensity storms resulting from climate change. Blue roofs can be designed as either conventional roofing systems or as an inverted roof membrane assembly (IRMA). These systems temporarily store and slowly release precipitation into the municipal stormwater system. To achieve a functioning and well-performing blue roof, designers are challenged to determine the approach that is best suited for the particular needs of each project.

Roof layout options include no-slope systems with greater storage capacity, low-sloped roofs with potentially more limited storage capacity, and low-sloped roofs with check dams to increase capacity and facilitate some drainage. Blue roofs create two significant issues. First, they increase the load on the structure due to the weight of the stored water. Second, retaining water on the roof can accelerate deterioration of the roof membrane and increase the risk of water leakage.

To avoid these concerns, many designers are employing stormwater detention tanks to slow the release of stormwater. However, this requires back-of-house space. As designers and contractors continue to gain more experience with blue roof technology, roofing continue to innovate approaches for temporarily storing stormwater, and the use of these systems is expanding to more urban jurisdictions concerned with stormwater management. Owners should expect to see blue roofs and stormwater management strategies implemented on more projects in the future.

4. Windows and glazing

The current, market-driven, design trend mandates large areas of fenestration to create desirable space for building occupants. Buildings with large areas of glazing now provide significantly better thermal performance compared to highly-glazed buildings constructed decades ago that used solid metal frames and monolithic glazing. Energy-efficient improvements to fenestration systems currently on the market include thermally broken frames, insulating glass units (IGU), triple-pane glass, suspended film glass, dynamic glass (electrochromic, thermochromic, and others), and double-glazed wall systems.

Thermal break technology has improved, resulting in stronger materials that can more readily accept bigger IGUs and triple-pane glass, reducing conductive heat loss and improving performance. Improvements in IGU technology with low-e coatings and thin films, high-efficiency spacers, triple-pane glass, or suspended film glass help reduce solar heat gain and decrease the U-value of glazing systems. Self-shading glass automates the process for reducing glare, reducing solar heat gain and increasing comfort for the users. Creative use of these options combined with inventive planning of interior space brings light further into the building. Integrating daylight controls further limits energy use.

However, the trend to provide large areas of fenestration runs counter to changes in the model building codes that are discouraging large glazing areas on building enclosures. As mechanical system improvements approach a point of diminishing returns, the burden of energy-efficient design falls more prevalently on the building-enclosure design. Even with improvements, glazing systems are still significantly less energy efficient than the opaque cladding systems that the model building codes favor. Therefore, further energy reduction will need to come from improved fenestration systems as long as the trend toward large amounts of glazing on buildings continues.

5. Weather-resistant barriers

Current building codes require that designs for enclosure systems include waterproofing, vapor retarders, and air barriers, which have a significant impact on durability and energy efficiency. The waterproofing prevents bulk, liquid water from infiltrating to the interior of the building. The air barrier and vapor retarder both prevent water vapor migration but affect different transport mechanism of that migration. Vapor retarders prevent the diffusion of water vapor through materials, and air barriers prevent vapor migration via bulk air transport. Air barriers also have a direct effect on energy consumption by preventing transport of conditioned air through the enclosure.

The location of vapor retarders relative to the insulation is important, as vapor retarders in the wrong location may result in condensation within assemblies. The continuity of air barriers around the entire enclosure is important because air transports large volumes of moisture quickly, increasing the potential for condensation under some conditions. Air barriers also prevent the migration of conditioned/unconditioned air through the enclosure, which in turn helps the building be more energy efficient.

Using one membrane to create the air barrier, vapor retarder, and waterproofing membrane (collectively, the AVB) is potentially a good strategy.

Manufacturers of AVBs have continued to innovate and bring new products to market, and contractors continue to look for ways to more efficiently and effectively install the products. Further, designers and owners are becoming more aware of how critical the AVB is to provide energy efficiency, mitigate water and air leakage, and prevent condensation. Significant developments in technology and construction practice include:

• AVBs that meet fire code. Historically reliable and durable AVBs are made from self-adhered, rubberized-asphalt sheets, which when combined with combustible insulation materials, do not meet current NFPA requirements. As a result, AVBs have been redeveloped to include aluminum facers and/or to have a butyl backing in lieu of rubberized asphalt. The performance of these new membranes has been mixed and changes continue to be made, resulting in a limited track record of successful performance, which makes AVB selection difficult.

• Fluid-applied membranes to improve installation time and reduce cost. Although fluid-applied membranes can reduce construction time, they are also more dependent on installation workmanship to function properly, have a shorter track record, and undetermined durability. Integrating these materials with adjacent cladding systems can be challenging, requiring the introduction of a sheet membrane material to construct membrane transitions and terminations.

• More rigorous quality assurance programs during construction. These are designed to assess the performance of the AVB and its integration with cladding and fenestration systems. Owners and designers are more frequently requiring testing, including quantitative and qualitative testing of air barrier systems and transitions, water-infiltration testing of fenestration systems and the transitions, infrared thermography scans of exterior walls and roofing areas, and material adhesion testing. The growth in quality assurance programs is attributed to the understanding that performance issues with newer and untested systems are expected, and field testing is needed to increase the rate of success. Some of the increase in testing requirements can also be explained by the increased implementation of building-enclosure commissioning programs.

6. Cladding attachments and insulation

Thermally-broken cladding attachment systems that include integral thermal breaks in the subframing systems or are made of non-conductive materials help reduce the energy loss of the building. These systems are fairly new to the market and do not have a significant track record of long-term performance

Manufacturers are also innovating for single material systems, such as insulation (spray and rigid boards), to also perform as the waterproofing, air barrier, and vapor retarder.

In some systems, the insulation is replacing the sheathing normally installed over cold-formed metal framing. These systems, while capable of passing testing when installed in laboratory conditions, are susceptible to water and air leakage in the field unless installed perfectly and even then are at risk as they age. Further, integration of fenestration and other penetrations through the system can be difficult, and in some cases, impossible to resolve reliably and durably. These systems simplify the construction of exterior wall systems and reduce cost but not without potentially compromising performance.

7. Green walls

Green walls are being adopted on more buildings as designers look use vegetation on vertical surfaces. Historically, green walls were limited to ivy growing up masonry buildings, which leads to damage to the masonry over time. Now, less aggressive plantings can be established to provide more green cover and help reduce rainwater runoff down walls, assist with cooling, especially on direct sun elevations, and provide a more pleasing aesthetic. Cladding systems can be designed to improve durability to the vegetation, and support structures can be designed to separate the planting and cladding. However, maintenance concerns similar to those of the green roofs exist for the wall system, including access to backup materials, and the need for periodic pruning to avoid vegetation growth over fenestration, which can be difficult for taller buildings.

8. Snow and ice protection

In the past few years, the number of reported cases of ice and snow falling from facades of relatively new buildings has increased. The issue is apparent on city streets in cold climates during and shortly after snow and has recently been the subject of news coverage. Some question whether the increase in these incidents is correlated to the increase in high-performing new buildings. Presently, the industry is researching this question. Given the attention and potential hazard that this issue presents, it has become a priority to better understand the underlying causes and possible remedies. The issue is complicated by the significant number of variables that affect the potential for falling snow and ice, including projections becoming more common in contemporary facades, design of thermally-efficient enclosures that limit heat loss from the interior (cooling the surface of projections), and various materials used, including metal and glass, which may not retain snow and ice as readily as cladding systems used in the past.

Some preliminary data is available to guide the discussion on some design approaches for mitigating falling snow and ice, but it is limited and the effectiveness of the solutions can be uncertain under some applications. We expect that the understanding of this issue will grow with continued research and discussions. Additional design guidance should be expected, but this issue is relatively new and will continue to challenge the industry for years to come. Building designers and owners should review their designs with consideration for these possible effects and incorporate retention, protection, or melting systems where the hazards are high.

To develop high-quality, energy-efficient building enclosures, building owners must embrace technological advances in enclosure materials and design. However, to reap the benefits of the advances without compromising durability or project budgets, the project team must understand the intended use, limitations, and potential for unanticipated results. If employed thoughtfully and with full knowledge of the benefits and limitations, building-enclosure technology can help building owners achieve their visions for high functioning, aesthetically innovative, and efficient building designs. Project teams must also recognize and acknowledge that the exterior enclosure can only do so much. Location, climate zone, siting, lighting, mechanical systems, and a myriad of other factors will also influence whether the building is truly energy efficient and high performing. n

Peter M. Babaian, P.E., S.E., principal with Simpson Gumpertz & Heger, serves as the building technology division head for the Chicago office, and leads the firm’s building enclosure commissioning practice. Emily R. Hopps, P.E., is an associate principal and leads the firm’s flooring practice. Matthew J. Normandeau, P.E., LEED AP, is a senior project manager who performs building enclosure investigations and condition assessments, designs repairs, and consults on the design for new building enclosures.

Email questions to edward.sullivan@tradepress.com.

posted on 9/21/2017

Comments

Source: Commercial Roofing

No comments yet.